1.4845 Stainless Steel – Heat Resistant Austenitic Alloy for Industrial Use

The material 1.4845, also known as AISI 310S, X15CrNi25-21, or UNS S31008, is an austenitic chromium-nickel stainless steel with high heat resistance. Its chemical composition allows for use in oxidizing atmospheres at temperatures up to approximately 1050 °C. This makes it a reliable choice for applications involving intense thermal stress.

Heat-resistant Stainless Steel

1.4845 || AISI 310S/H

Operating Temperature Range for 1.4845 material

- How heat-resistant is 1.4845?

This alloy is heat resistant in oxidizing atmospheres up to approximately 1050 °C. For even higher temperature applications, material 1.4841 is recommended.

Material Behavior in Different Atmospheres

How does 1.4845 perform under various conditions?

In oxidizing environments, the material remains scale-resistant and structurally stable. However, its resistance is limited in reducing, sulfur-containing, or carburizing conditions. In such environments, alternative materials should be considered.

Is 1.4845 Stainless Steel Magnetic:

Due to its austenitic structure, 1.4845 stainless steel is non-magnetic—even after cold working, it maintains low magnetic permeability.

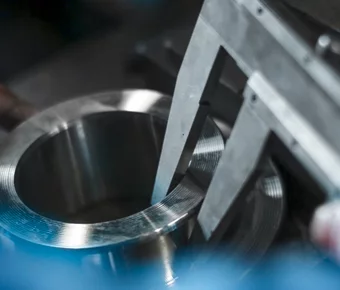

Common Applications and Industry Use of 1.4845 Material

1.4845 stainless steel is commonly used in:- Industrial furnaces and thermal processing systems

- Exhaust systems and furnace tubes

- Chemical equipment exposed to heat

- Petrochemical components

The combination of heat resistance, corrosion protection, and mechanical strength makes it a widely applicable material in high-temperature environments.

Heat Treatment and Processing Temperatures

1.4845 material can be processed at the following temperatures:- Hot forming: 1150 – 800 °C, followed by slow cooling in air

- Solution annealing (condition +AT): 1050 – 1150 °C, with quenching in air or water

Welding methods suitable for 1.4845 stainless steel

- The alloy is weldable using TIG, MIG, and manual arc welding techniques. Due to the high chromium and nickel content, suitable filler metals must be selected. Care should be taken to minimize risks of carbide precipitation and hot cracking.

Comparison between 1.4845 and 1.4841

- Both grades are heat-resistant, but 1.4845 contains less carbon than 1.4841, providing better resistance to scaling. For very high-temperature use where enhanced oxidation resistance is needed, 1.4841 is generally preferred.

Chemical Composition of 1.4845 (AISI 310S)

The alloying elements of 1.4845 material are specifically balanced for high-temperature service (This composition provides strong resistance to oxidation and scaling at elevated temperatures.):

| Value | Percentage |

|---|---|

| Chromium (Cr): | 24.0 – 26.0 % |

| Nickel (Ni): | 19.0 – 22.0 % |

| Carbon (C): | max. 0.10 % |

| Manganese (Mn): | min. 0 % - max. 2.00 % |

| Silicon (Si): | min. 0 % - max. 1.50 % |

| Phosphorus (P): | min. 0 % - max. 0.045 % |

| Sulfur (S): | min. 0 % - max. 0.015 % |

| Nitrogen (N): | min. 0 % - max. 0.11 % |

Mechanical values at room temperature

At 20 °C, 1.4845 stainless steel exhibits the following mechanical properties (These values support the material’s use under continuous thermal load):

| Hardness HB | ≤ 192 |

| Yield strength Rp 0.2 | ≥ 210 N/mm2 |

| Tensile strength Rm | 550 – 750 N/mm2 |

| Elongation A5 | ≥ 35 % |

Creep strength

Creep strength is the mechanical initial stress that causes a material to break after a certain period of stress duration and at a constant temperature above the transition temperature under constant tensile force.

| Temperature | 1 000 h | 10 000 h | 100 000 h |

|---|---|---|---|

| Temperature: 600 °C | 1 000 h: 170 N/mm2 | 10 000 h: 130 N/mm2 | 100 000 h: 80 N/mm2 |

| Temperature: 700 °C | 1 000 h: 80 N/mm2 | 10 000 h: 40 N/mm2 | 100 000 h: 18 N/mm2 |

| Temperature: 800 °C | 1 000 h: 35 N/mm2 | 10 000 h: 18 N/mm2 | 100 000 h: 7 N/mm2 |

| Temperature: 900 °C | 1 000 h: 15 N/mm2 | 10 000 h: 8,5 N/mm2 | 100 000 h: 3 N/mm2 |

Creep limit

Creep limit is the initial stress that leads to a specified plastic deformation under constant tensile stress at a predetermined temperature and duration of stress.

| Temperature | 1 % Creep limit for 1 000 h | 10 000 h |

|---|---|---|

| Temperature: 600 °C | 1 % Creep limit for 1 000 h: 100 N/mm2 | 10 000 h: 90 N/mm2 |

| Temperature: 700 °C | 1 % Creep limit for 1 000 h: 45 N/mm2 | 10 000 h: 30 N/mm2 |

| Temperature: 800 °C | 1 % Creep limit for 1 000 h: 18 N/mm2 | 10 000 h: 10 N/mm2 |

| Temperature: 900 °C | 1 % Creep limit for 1 000 h: 10 N/mm2 | 10 000 h: 4 N/mm2 |

Coefficient of thermal expansion

Coefficient of thermal expansion for heat-resistant alloys, which have a high coefficient of thermal expansion and low thermal conductivity, leading to temperature and stress differences in a component or assembly. The coefficient of thermal expansion is expressed by the proportional length change for each degree of temperature increase, usually as 10 –6 K –1.

| Temperature | Coefficient of thermal expansion |

|---|---|

| Temperature: 200 °C | Coefficient of thermal expansion: 15,5 |

| Temperature: 400 °C | Coefficient of thermal expansion: 17,0 |

| Temperature: 600 °C | Coefficient of thermal expansion: 17,5 |

| Temperature: 800 °C | Coefficient of thermal expansion: 18,5 |

| Temperature: 1 000 °C | Coefficient of thermal expansion: 19,0 |

- EN 10216-5

- EN 10297-2

- SEW 470

- ASME SA312

The information provided on this page is non-binding. It serves only as orientation.

We cannot guarantee the results in processing and application of the products.

Tables and rates

Not the right steel available?

You will find the complete program for stainless steel piping systems in various materials for the highest requirements with us.