1.4828 Stainless Steel – The Robust Stainless Steel for Thermal Applications

The 1.4828 material, also known as AISI 309 or X15CrNiSi20-12, is an austenitic, heat-resistant stainless steel that is widely used in furnace construction and thermally stressed components. Thanks to its good mechanical strength at elevated temperatures and improved scaling resistance compared to older standard grades like 1.4713, 1.4828 stainless steel is ideal for use in applications ranging from 800 °C to 1000 °C.

Physical Properties at 20 °C

1.4828 || AISI 309

- Density: 7.9 kg/dm³

- Electrical Resistivity: 0.85 Ω·mm²/m

- Thermal Conductivity: 15 W/m·K

- Specific Heat Capacity: 500 J/kg·K

- Magnetism: Not magnetic (non-magnetic)

Typical Applications of 1.4828 Material

1.4828 stainless steel is used in a wide range of industries, especially where high thermal loads are present. Common applications include:- Furnace construction, grates, screens

- High-temperature equipment manufacturing

- Chain industry, chemical and petrochemical sectors

- Automotive and cement industries

Chemical Composition of 1.4828 (AISI 309)

The chemical composition of this 1.4828 stainless steel is well-balanced to ensure heat resistance:

| Value | Proportion |

|---|---|

| Chromium (Cr): | 19.0 – 21.0 % |

| Nickel (Ni): | 11.0 – 13.0 % |

| Silicon (Si): | 1.5 – 2.5 % |

| Carbon (C): | min. 0 % – max. 0.20 % |

| Manganese (Mn): | min. 0 % – max. 2.00 % |

| Phosphorus (P): | min. 0 % – max. 0.045 % |

| Sulfur (S): | min. 0 % – max. 0.015 % |

| Nitrogen (N): | min. 0 % – max. 0.11 % |

Mechanical Properties at Room Temperature

| Hardness (HB) | ≤ 223 |

| Yield strength Rp 0.2 | ≥ 230 N/mm2 |

| Tensile strength Rm | 550 – 780 N/mm2 |

| Elongation A5, 65 | ≥ 30% |

| Modulus of Elasticity: | approx. 196 kN/mm² |

Is 1.4828 Stainless Steel Easy to Weld?

Yes, the 1.4828 stainless steel can be welded using all common welding processes. Preheating or post-weld heat treatment is usually not necessary. However, heat input should be controlled to avoid embrittlement of the material.

Is 1.4828 Suitable for High-Temperature Applications?

Yes, 1.4828 AISI 309 is heat-resistant in the temperature range of 800 °C to 1000 °C and maintains good scaling resistance in air atmospheres within this range. This makes it particularly suitable for applications with continuous thermal stress.

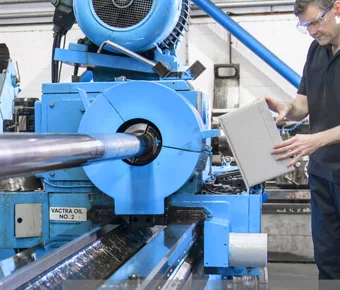

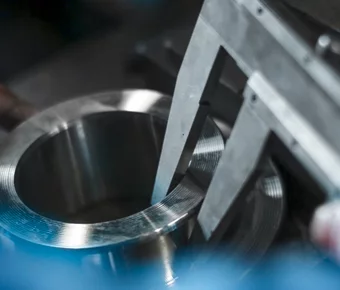

Machining and Forming

During machining, 1.4828 AISI 309 tends to form carbides, which increases tool wear. Therefore, high-quality tools and effective cooling are recommended. Cutting speeds and depths should be kept low.

Hot forming takes place between 1150 °C and 800 °C, followed by rapid cooling. Solution annealing can be carried out between 1050 °C and 1150 °C, followed by air or water cooling.

Is It Corrosion-Resistant in Certain Gas Atmospheres?

In oxidizing and reducing sulfur-containing gases, resistance is limited – a maximum operating temperature of 650 °C is recommended for these environments. In carburizing or nitrogen-rich, low-oxygen atmospheres above 900 °C, the 1.4828 material shows only limited resistance.

Comparison with 1.4841 and AISI 310S (1.4845)

Similarities and Differences

| Material | 1.4828 (AISI 309) | 1.4841 (AISI 314) | 1.4845 (AISI 310S) |

|---|---|---|---|

| Material: Max. Scaling Resistance | 1.4828 (AISI 309): up to 1000 °C | 1.4841 (AISI 314): up to 1150 °C | 1.4845 (AISI 310S): up to 1050 °C |

| Material: Chromium Content | 1.4828 (AISI 309): 19–21 % | 1.4841 (AISI 314): 24–26 % | 1.4845 (AISI 310S): 24–26 % |

| Material: Nickel Content | 1.4828 (AISI 309): 11–13 % | 1.4841 (AISI 314): 19–22 % | 1.4845 (AISI 310S): 19–22 % |

| Material: Recommended Temperature Range | 1.4828 (AISI 309): 800–1000 °C | 1.4841 (AISI 314): 900–1120 °C | 1.4845 (AISI 310S): up to 1050 °C |

If you’re looking for a cost-effective solution for applications up to 1000 °C without high corrosion exposure, 1.4828 material is an excellent choice. For higher temperatures or aggressive environments, materials such as 1.4841 or 1.4845 may be more suitable.

Standards for pipes

- EN 10217-7

- EN 10296-2

- SEW 470

- ASME SA 312

The information provided on this page is non-binding. It serves only as orientation.

We cannot guarantee the results in processing and application of the products.

Tables and rates

Not the right steel available?

You will find the complete program for stainless steel piping systems in various materials for the highest requirements with us.